Design & preparation

Once deconstructed, the timepieces and parts are then painstakingly reimagined over one month of design work to expose the tremendous intricacies and human ingenuity involved in fine watchmaking.

Selection & Grading

Each and every gear, barrel, wheel, spring, escapement wheel, pinion, bridge, and hands is storied. The vast majority of the components are of Swiss origin. Each part is individually and carefully reviewed similar to the process of selecting and grading the most precious diamonds.

Positioning in Lucite®

Components are restored, polished and meticulously positioned, balanced in precious, crystal clear shatter-resistant Lucite®.

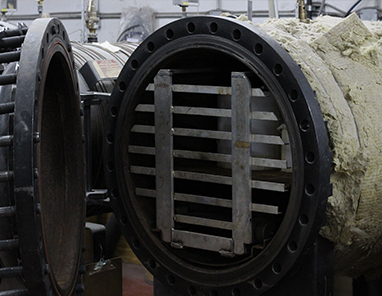

Placement & Baking

The artisans place the components with a highly controlled method, ensuring total balance of size and color within the piece. Each sculpture then begins an arduous process of repeatedly placing components in layers of Lucite®, and then baking in highly pressurized 1,000° Oracle ovens.

Masterminds in freezing time, Berd Vay’e offers an exclusive look into the secret inner-workings of watchmaking through its show-stopping, limited edition sculptures. Each and every gear, barrel, wheel, spring, escapement wheel, pinion, bridge, and hands is storied. Components are restored, polished and meticulously positioned, balanced in precious, crystal clear shatter-resistant Lucite®.

berdvaye

berdvaye